With the growing awareness of environmental protection, biodegradable materials have attracted increasing attention as an eco-friendly alternative. In this article, we will introduce the production process of MVI ECOPACK biodegradable materials, including raw material selection, production technology, and compare it with the production process of traditional materials to highlight the environmental advantages of biodegradable materials.

MVI ECOPACK addresses the production process of biodegradable materials and compares it with traditional materials by implementing the following strategies:

Advanced Technology Adoption: MVI ECOPACK utilizes cutting-edge technology in its production processes to optimize efficiency and minimize environmental impact. This includes innovative methods for raw material processing, mixing, molding, and product finishing.

Research and Development: The company invests in ongoing research and development efforts to continually improve its production processes. This involves exploring new techniques and materials that enhance biodegradability while maintaining product quality and performance.

Collaboration with Experts: MVI ECOPACK collaborates with industry experts and environmental organizations to ensure its production processes adhere to the highest standards of sustainability. By leveraging external expertise, the company can identify areas for improvement and implement best practices.

Lifecycle Assessment: MVI ECOPACK conducts comprehensive lifecycle assessments to evaluate the environmental impact of its biodegradable materials throughout their entire lifecycle. This includes assessing factors such as resource use, energy consumption, emissions, and waste generation.

In comparison to traditional materials, MVI ECOPACK's approach offers several advantages:

Environmental Sustainability: MVI ECOPACK prioritizes the use of renewable resources and minimizes energy consumption and emissions in its production processes. This stands in stark contrast to traditional materials, which often rely on non-renewable resources and generate significant environmental pollution.

Biodegradability: Unlike many traditional materials that persist in the environment for years or even centuries, MVI ECOPACK's biodegradable materials break down naturally over time, reducing their impact on ecosystems and wildlife.

Resource Efficiency: MVI ECOPACK optimizes resource utilization throughout its production processes, minimizing waste and maximizing the use of recycled and recyclable materials. This promotes a more circular economy and reduces the reliance on finite resources.

Consumer Awareness: By highlighting the environmental benefits of its biodegradable materials, MVI ECOPACK raises awareness among consumers about the importance of making sustainable choices. This encourages broader adoption of eco-friendly alternatives and contributes to positive environmental change.

Production Process of Biodegradable Materials:

Raw Material Selection

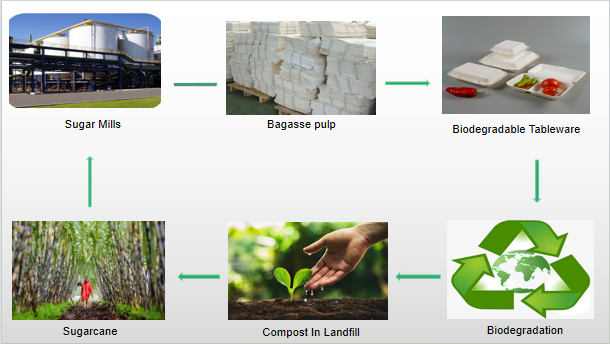

The production process of MVI ECOPACK biodegradable materials begins with careful selection of raw materials. We mainly choose raw materials from renewable resources such as sugarcane bagasse pulp, cornstarch pulp , etc. These resources are renewable and biodegradable, aligning with the principles of environmental protection and sustainable development.

Production Technology:

Raw Material Processing: Selected renewable resources undergo special treatments such as crushing, grinding, etc., to facilitate subsequent production processes.

Mixing and Molding: Processed raw materials are mixed with a certain proportion of additives (such as plasticizers, fillers, etc.) and then molded into desired shapes through processes like extrusion, injection molding, etc.

Processing and Forming: The molded products undergo further processing such as mold forming, surface treatment, etc., to improve the quality and performance of the products.

Testing and Packaging: Finished products undergo rigorous testing to ensure they meet relevant standards and requirements before being packaged and prepared for shipment.

Comparison with Traditional Materials

In the production process, MVI ECOPACK biodegradable materials differ significantly from traditional materials:

Raw Material Selection: Traditional materials typically use petrochemical products as the main raw materials, while MVI ECOPACK chooses renewable resources, offering higher environmental friendliness and sustainability.

Production Technology: The production process of traditional materials often involves high temperatures, pressures, etc., consuming a considerable amount of energy, whereas the production process of MVI ECOPACK is more environmentally friendly with lower energy consumption.

Product Performance: While traditional materials may have better performance in some aspects, MVI ECOPACK biodegradable materials exhibit significant environmental advantages and do not cause long-term pollution to the environment.

Lifecycle Impact: Traditional materials have a significant lifecycle impact, including production, usage, and disposal stages, causing irreversible harm to the environment. In contrast, MVI ECOPACK biodegradable materials can reduce this impact to some extent, lessening the burden on the environment.

In comparison, the production process of MVI ECOPACK biodegradable materials is more environmentally friendly than traditional materials, demonstrating clear advantages and aligning with the principles of sustainable development, deserving further promotion and application.

Overall, MVI ECOPACK's approach to addressing the production process of biodegradable materials and comparing it with traditional materials demonstrates a commitment to sustainability and innovation. Through continuous improvement and collaboration, the company aims to lead the transition towards a more environmentally conscious future.

You Can Contact Us:Contact Us - MVI ECOPACK Co., Ltd.

E-mail:orders@mvi-ecopack.com

Phone:+86 0771-3182966

Post time: Mar-15-2024