WHY MOLDED FIBER TABLEWARE IS INALLY A REALISTIC ALTERNATIVE TO PLASTIC

Publisher: MVI ECO

2026/2/11

Molded Fiber’s Growth as a Plastic Replacement Isn’t Pulp Fiction

Table of Contents |

| 1.What Is Molded Fiber Tableware?2.Why It’s Taking Off Now ——After Years of Failed Alternatives3.What Makes Good Molded Fiber Tableware?4.The Honest Truth About Composting

5.Does It Actually Work for Real-World Use? 6.What This Means for You 7.What’s Coming Next 8.Frequently Asked Questions |

You’ve probably noticed something different about your takeout containers lately. They feel heavier, more substantial than those flimsy plastic boxes you used to get. And that’s no accident.What you’re holding is probably molded fiber tableware—plates, bowls, and containers made from plant fibers like sugarcane waste, bamboo, or recycled paper. And unlike the dozens of “eco-friendly” alternatives that came before it, this one is actually replacing plastic at scale.Here’s why that matters to you.

What Is Molded Fiber Tableware?

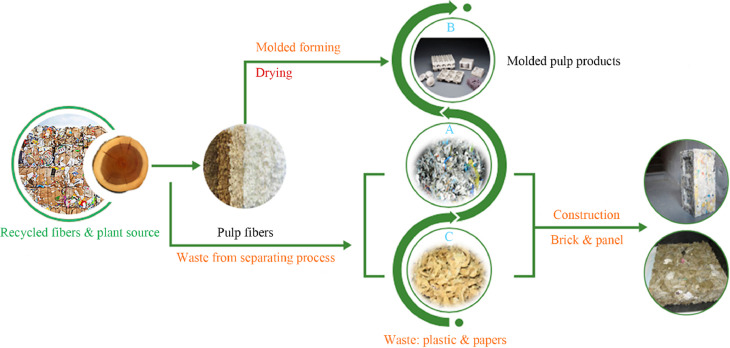

Integrated molded fiber product manufacturing process using recycled fibers as fiber sources, with wastes turned to construction materials (bricks, panels etc.)

Think of it as giving agricultural waste a second life. When sugarcane is processed for juice, you’re left with bagasse—a fibrous pulp that used to be burned or thrown away. Same goes for the stalks left after wheat harvests, or bamboo trimmings.Now, manufacturers take these leftovers, mix them with water to create a pulp, and mold them into containers using heat and pressure. The result is surprisingly sturdy tableware that naturally biodegrades within a few months.The key difference from traditional paper products? These containers can handle hot soup without falling apart and greasy food without leaking through. That’s because of how the plant fibers naturally bond together, creating a strong mesh structure.

Why It’s Taking Off Now ——After Years of Failed Alternatives

We’ve heard promises about “eco-friendly alternatives” before. Remember when biodegradable plastics were supposed to solve everything? Or when corn-based packaging was the next big thing?Those solutions ran into the same problems: they either didn’t perform as well as plastic, cost too much, or turned out to have their own environmental issues.So what changed with molded fiber tableware?

1. The Technology Got Better

Food service companies in the US reduced their plastic packaging waste by over 50% after switching to molded fiber products. That’s not a small test—that’s actual, measurable impact.

The breakthrough came from solving the moisture problem. Early fiber containers would get soggy with hot or greasy foods. New coating technologies—many made from plant-based materials rather than chemicals—changed that completely.

Studies show these new coatings block oil and grease effectively while still letting the container biodegrade naturally. Some even have antimicrobial properties that keep food safer.

2. Major Companies Started Using It

In 2025, Google made all packaging for its Pixel phones, Fitbit devices, and Nest products completely plastic-free using molded fiber. They switched because the fiber packaging protected products as well as plastic while cutting environmental impact. When tech companies start trusting fiber containers to ship delicate electronics, that tells you something about durability.

Starbucks rolled out compostable fiber lids in California and Colorado. Fast-food chains are adopting fiber containers for hot and cold foods. Even hospitals switched to fiber bedpans and medical trays because they’re cheaper than sterilizing reusable items.

3. The Price Gap Closed

Five years ago, molded fiber products cost 40-60% more than plastic equivalents. Today, that premium has dropped to 15-30%, and for large orders, sometimes there’s no difference at all.

Why? Manufacturing got more efficient. Raw materials are basically free (agricultural waste). And as more companies made the switch, production scaled up.

Plus, many cities now charge disposal fees for plastic waste or ban certain plastic products entirely. When you factor in those costs, fiber often comes out ahead.

What Makes Good Molded Fiber Tableware?

Not all fiber products are created equal. Here’s what actually matters:

Heat Resistance Good molded fiber tableware holds up to 200°F without deforming. That covers hot coffee, soup, and most prepared foods. If you’re serving something extremely hot, check the specifications.

Load Capacity Quality products can hold 1-2 pounds of food without sagging or breaking. That’s comparable to plastic foam containers.

Moisture Barriers This is where coating technology matters. Look for products with bio-based coatings that prevent grease and liquid from seeping through. The container should stay rigid even with wet foods.

Composting Certification Check for BPI (Biodegradable Products Institute) certification. This means the product has been independently tested and verified to break down in commercial composting facilities within 60-90 days.

No PFAS Chemicals These “forever chemicals” were used in some older products for grease resistance. They’re terrible for health and environment. Make sure your products are certified PFAS-free.

The Honest Truth About Composting

Here’s something most companies won’t tell you upfront: “compostable” doesn’t always mean you can toss it in your backyard compost pile.

Most molded fiber tableware is designed for industrial composting facilities—specialized operations that maintain high temperatures and controlled conditions. In those facilities, fiber containers break down completely within 60-90 days.But only about 185 large-scale composting facilities exist across the US that can handle this volume. If your city doesn’t have one, your “compostable” container might end up in a landfill.The good news? Even in landfills, fiber products break down in months rather than the centuries plastic takes. And as more businesses switch to compostable products, more cities are building composting infrastructure. San Francisco now processes 600 tons of compostable food service products annually—up from basically zero a decade ago.

So while the system isn’t perfect yet, it’s improving rapidly.

Does It Actually Work for Real-World Use?

Let’s look at what businesses report after making the switch:

Restaurants: One major fast-casual chain reduced landfill-bound packaging by 60% in one year. Customer complaints about packaging performance? None. In fact, customer satisfaction scores improved because diners appreciated the sustainability effort.

Catering Companies: Several event services achieved zero-waste certification by switching to fiber tableware combined with composting services. They report no increase in broken plates or customer issues.

Food Trucks: Operators love that fiber containers are lightweight (reducing transportation costs) but sturdy enough to handle messy foods like burgers and tacos.

Corporate Cafeterias: Universities and companies switching to fiber report significant waste reduction without the hassle of washing reusable dishes.

The pattern is clear: when properly selected for the application, molded fiber tableware performs as well as plastic alternatives while solving the waste problem.

What This Means for You

If You’re a Business Owner:

Consider molded fiber tableware if:

- Your city has plastic restrictions (many do now)

- Your customers value sustainability (most do)

- You want to reduce long-term waste disposal costs

- You’re in a sector facing PFAS liability concerns (food service, healthcare)

Wait a bit longer if:

- You operate in a very cost-sensitive market with no regulatory pressure

- Your local area has zero composting infrastructure

- You need specialized applications that current fiber products can’t handle

If You’re a Consumer:

When you see fiber tableware at a restaurant or event:

- Yes, it’s generally safe for hot and cold foods

- No, it won’t fall apart during your meal (if it’s quality product)

- Check if your local waste management accepts it for composting

- If not, it still beats plastic even in a landfill

Questions to Ask Suppliers:

- Is this certified PFAS-free?

- What’s the tested heat resistance?

- Do you have BPI composting certification?

- What’s your minimum order quantity?

- Can I get samples to test with our actual menu items?

What’s Coming Next

The innovation isn’t stopping. Here’s what’s in development:

Customizable Barriers: New coating technologies let manufacturers tune products for specific foods. Extra grease resistance for pizza. Better moisture barrier for soup. Antimicrobial coating for raw meat packaging.

Lighter Weight Products: Using AI and computer modeling, companies are designing containers that use 20-30% less material while maintaining strength. That means lower shipping costs.

Better Aesthetics: Transfer molding techniques are creating smoother surfaces that look and feel more premium. Some products are indistinguishable from plastic until you check the label.

Agricultural Partnerships: More farms are partnering with packaging companies to sell crop waste directly. This creates new revenue for farmers while securing stable raw materials for manufacturers.

Frequently Asked Questions

Q: Will molded fiber containers hold hot soup without leaking?

A:Yes, if properly coated. Look for products specifically rated for hot liquids.

Q: Can I microwave molded fiber tableware?

A:Most products are microwave-safe, but always check the label for your specific product.

Q: How long does it take to biodegrade?

A: 60-90 days in industrial composting facilities. Several months in landfills. Much faster than plastic’s centuries.

Q: Is it more expensive than plastic?

A:Currently 15-30% more for basic products, but the gap is closing rapidly. Large-volume orders often reach price parity.

Q: Where can I compost it?

A:Check with your local waste management. About 185 US facilities handle commercial composting. San Francisco, Seattle, Portland, Austin, and other cities have programs.

Q: Is it safe for food?

A:Yes, when properly manufactured and certified. Look for FDA approval and PFAS-free certification.

Q: Does it feel cheap or flimsy?

A:Good quality molded fiber actually feels more substantial than foam containers. It’s rigid and sturdy.

Q: Can it handle greasy food?

A:Modern coatings make it grease-resistant. Pizza, burgers, and fried foods work fine.

|

Want to Achieve Zero Waste for Your Food Service Business? Our professional eco-team offers consulting services to help you develop a comprehensive compostable packaging solution, including home compostable tableware options. Contact us to align your business with sustainable practices and achieve your zero-waste goals together. |

-The End-

Related Articles:

CAN YOU REALLY HAVE A HAND-FREE, ZERO-WASTE KITCHEN?THE TRUTH ABOUT TRULY COMPOSTABLE PLATE

Sturdy & Truly Compostable? Your Guide to Choosing Bagasse Straws & Dodging Greenwashing

Why Sustainable Bagasse Packaging Is the Future of Food Delivery Industry?

IS BAGASSE TABLEWARE SAFE FOR KIDS? EVERY PARENTS SHOULD KNOW THESE.

SUGARCANE BAGASSE PLATES vs PAPER PLATES : WHAT’S THE REAL DIFFERENCE?

TOP5 Popular Biodegradable Tableware Materials: 2025 Market Insights & Business Guide

Web: www.mviecopack.com

Email:orders@mvi-ecopack.com

Telephone: 0771-3182966

Post time: Feb-11-2026