GREENWASHING IN PACKAGING: 7 RED FLAGS EVERY BUYER SHOULD KNOW

Publisher: MVI ECO

2026/2/11

With online shopping exploding and consumer goods production at an all-time high, sustainable packaging has never been more critical. Yet as demand for eco-friendly solutions grows, so do misleading claims from companies looking to cash in on the green movement.Last month, a Portland restaurant owner spent $8,000 on ”compostable” bowls—only to have her composting facility refuse them. The supplier’s certification? It was for a completely diferent product. She’s not alone. A 2023 European Commission study found that 42% of environmental claims are exaggerated or false. Inpackaging specifically, 60% of “biodegradable” products fail to meet any recognized standard.This practice—known as greenwashing—doesn’t just waste money. It underminesgenuine sustainability eforts, confuses buyers, and erodes trust in an industry trying to solve real environmental problems.Here’s how to spot the fakes and make informed purchasing decisions.

What Is Greenwashing in Packaging?

Greenwashing is when companies market products as environmentally friendlywithout the substance to back it up. The term was coined in 1986 by environmentalist Jay Westerveld, who called out hotels promoting towel reuse to ”save the planet”—when they really just wanted to cut laundry costs.Today, greenwashing in packaging often involves vague terms like ”green,” ”eco- friendly,” ”bio-based,” and ”biodegradable” without evidence or certifications to support these claims. These deceptive practices mislead consumers, waste resources, and make it harder for genuinely sustainable companies to compete.

Why Packaging Greenwashing Matters

Industries relying heavily on packaging—electronics, consumer goods, food service— have created a plastic waste crisis. As environmental consequences becomeapparent, companies rush to position themselves as sustainability leaders.Unfortunately, this has led to an explosion of greenwashing tactics.

The stakes are high:

. 70% of U.S. consumers care more about sustainability than in the past (Statista, 2024)

. The U.S. generates 48 million tons of plastic waste annually

. Only 5-6% is actually recycled (Department of Energy)

. The sustainable packaging market hit $266 billion in 2024, projected to reach $413 billion by 2030

When buyers can’t distinguish real solutions from fake ones, everyone loses—except the companies doing the greenwashing.

Red Flag #1: Vague and Misleading Terminology

What It Looks Like

Packaging covered in words like ”eco-friendly,” ”green,” ”natural,” or ”earth- conscious”—with zero specifics about what makes it sustainable.

Why It’s Problematic

These terms have no legal definition. A product labeled ”eco-friendly” might contain just 2% recycled content. We’ve seen companies call petroleum-based plastic “green” because they added plant-based dye.

For example, ”biodegradable” simply means an item can break down into smaller pieces over time—a process that applies to nearly all materials, including plastics, given enough time. It doesn’t specify how long, under what conditions, or whether the breakdown is actually beneficial.

What to Look For Instead

. Specific percentages: ”Contains 75% post-consumer recycled PET”

. Quantified benefits: ”Reduces carbon emissions by 32% vs. virgin plastic”

. Real standards: ”ASTM D6400 certified for industrial composting”

. Precise conditions: ”Compostable within 90 days at 60°C”

Quick Test: No numbers or standards = marketing luf.

Red Flag #2: Misleading Imagery and Symbols

What It Looks Like

Nature imagery (leaves, trees, green colors) that creates a false perception of

environmental responsibility. Or recycling symbols that don’t guarantee recyclability.

The Deception

Colors and nature-related symbols in branding aren’t regulated. Photos of forests can evoke sustainability while the actual product contributes to deforestation.

The Recycling Symbol Problem

One of the most widespread examples involves the recycling symbol—a number inside three interlocking arrows. While the numbers are resin identification codes indicating plastic type, they lead consumers to assume the plastic is recyclable.

The reality:

. Only #1 (PETE) and #2 (HDPE) are widely recycled (~75% of programs)

. #3-7 are rarely recycled in practice

. The EPA has asked the FTC to reconsider these symbols due to consumer confusion

According to 2023 EPA data:

. U.S. plastic recycling rate: 8.7%

. For packaging specifically: 14.5%

. Everything else gets landfilled or burned

Polystyrene (#6) is a prime example. Frequently marketed as ”recyclable,” it’s made from hydrocarbons derived from nonrenewable petroleum. Resistant to

decomposition, polystyrene occupies around 30% of landfill mass globally—yet only about 6 facilities nationwide actually recycle it.

What to Do

. Look for How2Recycle labels (from GreenBlue) with location-specific info

. Ask: ”What percentage of facilities in our region accept this?”

. Verify: ”Has the recycling market been stable for 3+ years?”

Red Flag #3: The “Biodegradable” Misrepresentation

The Problem

“Biodegradable” is the most abused term in packaging. Technically, everything biodegrades given enough time—that plastic fork will break down in about 450 years.

The Scandal

Between 2010-2019, millions of ”biodegradable” plastic bags were sold using oxo- degradable technology. Manufacturers claimed environmental breakdown. EU

research revealed they simply fragmented into microplastics, creating worse pollution. The EU banned them in 2021.

What Research Shows

A 2023 Plymouth University study tested 203 ”biodegradable” products:

. After 3 years in soil: 83% remained intact

. After 3 years in ocean: 91% showed no degradation

. Meeting real standards: Only 14%

The Standards That Actually Matter

ASTM D6400 (US) / EN 13432 (Europe):

. Requires 90% biodegradation within 180 days

. In industrial composting (58°C ±2°C, controlled humidity)

. Resulting compost must be non-toxic

. Requires third-party testing

The Infrastructure Gap

Companies may market packaging as ”biodegradable” when it only meets minimum regulatory standards and won’t break down in natural environments or standard

landfills.

Industrial composting facilities exist in only 185 U.S. cities—serving about 5% of the population. For 95% of consumers, ”compostable” products end up in landfills where they won’t break down.

Questions to Ask

1. ”What specific standard—ASTM D6400 or EN 13432?”

2. ”Home compostable or industrial compostable?”

3. ”Can you share third-party test results showing degradation rates?”

No clear answers = walk away.

Red Flag #4: Exaggerated Environmental Claims Without Proof

What It Looks Like

Companies highlighting a single positive attribute—”made with recycled content” — while ignoring broader environmental impact.

Common Tactics

. Hidden Trade-ofs: Promoting ”recycled content” while ignoring toxic production processes

. Minor improvements as major wins: ”30% less plastic!” compared to their own wasteful previous design

. Compliance as achievement: Advertising adherence to basic regulations as advanced sustainability

The “Ocean Plastic” Example

Between 2019-2023, brands launched products with ”ocean plastic.” Investigation revealed most programs collect plastic from coastal areas (within 50km) that might reach the ocean—it’s regular recyclable plastic from beaches, rebranded for

premium pricing.

Adidas sold 15 million shoes with ”ocean plastic” by 2021. Their partner defines

“ocean plastic” as plastic collected before it reaches the ocean. Better than nothing, but not the ”fishing plastic from the ocean” image most consumers envision.

The Carbon Offset Problem

A 2023 Carbon Market Watch study found 90% of corporate carbon ofset projects significantly overstated their impact. Projects claimed to ”prevent deforestation” of forests never actually threatened.

What Legitimate Claims Include

Good example: “Contains 100% post-consumer recycled plastic, reducing

greenhouse gas emissions by 60% and energy use by 70% compared to virgin plastic bottles, verified by independent third party.”

✓ Specific baseline

✓ Quantified impact

✓ Independent verification

Questions to Expose BS

1. ”Compared to what specific alternative?”

2. ”Who verified this? Can I see the full LCA report?”

3. ”What’s the complete lifecycle impact?”

Red Flag #5: The Bio-Based Confusion

What It Looks Like

Marketing emphasizing ”plant-based” or ”made from renewable resources” while staying silent about end-of-life disposal.

The Critical Distinction

. Bio-based = Made from plants

. Biodegradable = Breaks down naturally

. Compostable = Breaks down in composting

These are NOT the same.

Real Examples

PLA (Polylactic Acid):

. ✓ Bio-based (100% plant-derived from corn/sugarcane)

. ✗ Won’t biodegrade in normal conditions

. ✓ Compostable (industrial facilities only, 140°F+)

. ✗ Can’t be recycled (contaminates PET streams)

Bio-PE (Bio-based Polyethylene):

. ✓ Bio-based (from sugarcane)

. ✗ Not biodegradable

. ✗ Not compostable

. ✓ Recyclable (chemically identical to petroleum PE)

. Environmental benefit: ~75% lower production emissions

PHA (Polyhydroxyalkanoates):

. ✓ Bio-based (bacterial fermentation)

. ✓ Biodegrades (ocean, soil, home compost)

. ✓ Compostable anywhere

. Cost: 3-5x more expensive

Questions to Ask

1. ”Is this bio-based, biodegradable, compostable—or what combination?”

2. ”What happens at end-of-life in typical disposal?”

3. ”What infrastructure exists for proper disposal in our region?”

Red Flag #6: Lack of Supply Chain Transparency

What It Looks Like

Companies that advertise sustainable packaging materials while the rest of their production involves high-polluting processes.

Common Tactics

. Promoting one sustainable component while hiding unsustainable sourcing

. Marketing ”compostable” packaging from suppliers with destructive forestry practices

. Highlighting minor packaging changes while operating high-emission facilities

. Refusing to disclose full supply chain information

The TerraCycle Case

TerraCycle built reputation for innovative recycling. 2022 investigations revealed much of what they collected wasn’t actually recycled—it was warehoused or

landfilled. They promoted ”zero waste” while struggling with economic realities of recycling difficult materials. The gap between marketing and operations.

What Real Transparency Looks Like

Patagonia’s Footprint Chronicles:

. Publishes supply chain for every product

. Shows environmental impact by production stage

. Admits failures alongside successes

. ”We tried recycled polyester from bottles, but factory waste was more available. Here’s why.”

Interface’s Carbon Dashboard:

. Real-time carbon data published publicly

. Full methodology documented

. Third-party verified annually

Red Flag Responses

. ✗ ”That’s proprietary information”

. ✗ ”Our certification is pending”

. ✗ ”Here’s a marketing deck”

. ✗ Defensive when asked technical questions

What Honest Suppliers Provide

. ✓ Certification numbers (not just logos)

. ✓ Third-party test results

. ✓ Complete material composition

. ✓ Supply chain documentation

. ✓ Honest discussion of limitations

Red Flag #7: The Virgin Material Trap

The Problem

New environmental regulations push companies to use post-consumer recycled content (PCR) and reduce virgin materials. However, not enough recycled plastic exists for companies to meet mandates or sustainability commitments.

Why This Perpetuates Greenwashing

Companies claim sustainability commitments while continuing to rely on virgin materials—perpetuating a cycle that increases plastic waste.

The Manufacturing Challenge

Existing production lines are designed for virgin materials with consistent properties (melt low, color, grade). Recycled content varies in quality and performance. When recycled plastics don’t match virgin specifications:

. Companies face increased costs

. Product performance may be compromised

. Manufacturing processes require modification

. Cycle times must be adjusted

This forces many companies to continue using virgin plastics while marketing minor improvements as major sustainability achievements.

The Environmental Impact

Virgin plastics are derived from nonrenewable fossil fuels. Their production is

energy-intensive, resulting in considerable carbon emissions. Companies market packaging as ”sustainable” due to minor improvements while virgin material

reliance:

. Strains natural resources

. Contributes to global pollution

. Generates significant carbon emissions

. Perpetuates dependence on fossil fuels

The Real Solution: Compostable Materials

Fully sustainable solutions reduce environmental impact from the outset and break down naturally with minimal intervention. Compostable materials like Cruz Foam:

. Made from 70% upcycled food waste

. ASTM D6400 and D5338 tested for compostability

. Return to earth after use (unlike plastics that persist for centuries)

. Compatible with existing manufacturing equipment

. Eliminate need for energy-intensive recycling

Questions to Ask

1. ”What percentage is virgin vs. recycled material?”

2. ”Why can’t you use 100% recycled content?”

3. ”Have you considered truly compostable alternatives?”

4. ”What’s your plan to reduce virgin material dependence?”

How to Verify Claims Yourself

Check certification databases:

1. BPI Compostable: bpiworld.org/BPI-Public-Database

2. FSC Forest Products: info.fsc.org/certificate.php

3. How2Recycle: how2recycle.info

If the certification number isn’t listed, it’s not certified.

Corporate cafeteria (2023):

. Switched to ”recyclable” #5 PP containers

. Local MRF doesn’t accept #5

. Result: Zero environmental benefit, contaminated recycling stream

Cofee chain (2021):

. Marketed ”plant-based” cups heavily

. Customer backlash when cups weren’t actually compostable

. Result: Reputation damage from social media

This is the norm for buyers who don’t verify.

Why Greenwashing Backfires

Brands caught misrepresenting sustainability eforts face:

. Legal action for false advertising

. Reputation damage that’s hard to repair

. Customer backlash on social media

. Loss of competitive advantage as trust erodes

The Opportunity

Businesses that prioritize genuine sustainability:

. Build customer loyalty: 70% of consumers care more about sustainability

. Future-proof operations: Stay ahead of regulations

. Reduce costs long-term: Eliminate waste and improve efficiency

. Attract conscious consumers: Premium pricing for authentic sustainability

Your Verification Checklist

For every new supplier:

□ Google every certification mentioned

□ Verify in official databases (BPI, FSC, How2Recycle)

□ Ask for certification numbers

□ Request third-party test results

□ Ask the 6 key questions above

□ Check local recycling/composting infrastructure

□ Order samples for testing (orders >$5,000)

□ Search ”[supplier name] sustainability claims” online

□ Review supplier’s complete supply chain documentation

□ Confirm manufacturing process compatibility

Time investment: 2-3 hours for new supplier

Potential savings: Thousands to hundreds of thousands

Moving Toward Real Solutions

Why Your Choices Matter

When you demand proof and reject greenwashing:

. Support genuine innovation: Reward companies doing real work

. Punish deception: Remove market incentive for greenwashing

. Raise industry standards: Push all suppliers toward accountability

. Protect customers: Build authentic sustainability credentials

. Drive systemic change: Every informed buyer creates ripple efects

Real Impact Example

A hotel chain demanded verification from all suppliers in 2021. Within 18 months:

. 3 suppliers upgraded certifications to meet requirements

. 2 admitted exaggerated claims and lost contracts

. 1 partnered to develop genuinely compostable products

. Industry peers noticed and adopted similar standards

One buyer asking hard questions created measurable industry change.

Real Sustainable Solutions Exist

Innovation is happening with verified, tested solutions:

Compostable materials:

. Mushroom packaging (MycoComposite): Grows in molds, home-composts in 30 days

. Seaweed films (Notpla): Disappears in 4-6 weeks

. PHA bioplastics: Marine-degradable, home-compostable

. Agricultural waste fiber: Wheat straw, sugarcane bagasse that actually composts

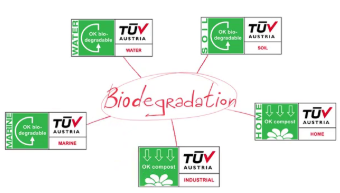

Verified certifications:

. ASTM D6400/D5338 for composability

. BPI and TÜV certified ingredients

. FSC for responsible forestry

. Third-party LCA verification

These solutions work. They’re certified. They compete against products that just claim to work.

Your purchasing decisions determine which survives.

Quick Resources

Verify certifications:

| . |

BPI Compostable Products: bpiworld.org/BPI-Public-Database |

| . | FSC Forest Products: info.fsc.org/certificate.php |

| . | How2Recycle Labels: how2recycle.info |

Regulations & Standards:

. FTC Green Guides: Official guidance on environmental claims

. ASTM D6400: Compostable plastics specification

. EN 13432: European composability requirements

. ISO 14040/14044: Lifecycle assessment standards

|

Want to Achieve Zero Waste for Your Food Service Business? Our professional eco-team offers consulting services to help you develop a comprehensive compostable packaging solution, including home compostable tableware options. Contact us to align your business with sustainable practices and achieve your zero-waste goals together. |

-The End-

Related Articles:

CAN YOU REALLY HAVE A HAND-FREE, ZERO-WASTE KITCHEN?THE TRUTH ABOUT TRULY COMPOSTABLE PLATE

Sturdy & Truly Compostable? Your Guide to Choosing Bagasse Straws & Dodging Greenwashing

Why Sustainable Bagasse Packaging Is the Future of Food Delivery Industry?

IS BAGASSE TABLEWARE SAFE FOR KIDS? EVERY PARENTS SHOULD KNOW THESE.

SUGARCANE BAGASSE PLATES vs PAPER PLATES : WHAT’S THE REAL DIFFERENCE?

TOP5 Popular Biodegradable Tableware Materials: 2025 Market Insights & Business Guide

Web: www.mviecopack.com

Email:orders@mvi-ecopack.com

Telephone: 0771-3182966

Post time: Feb-13-2026